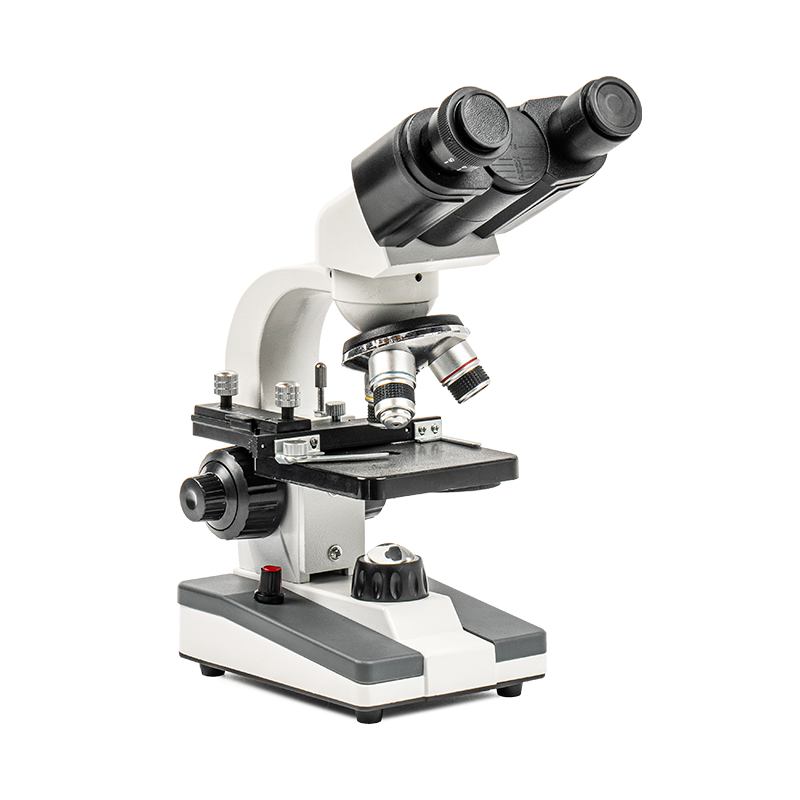

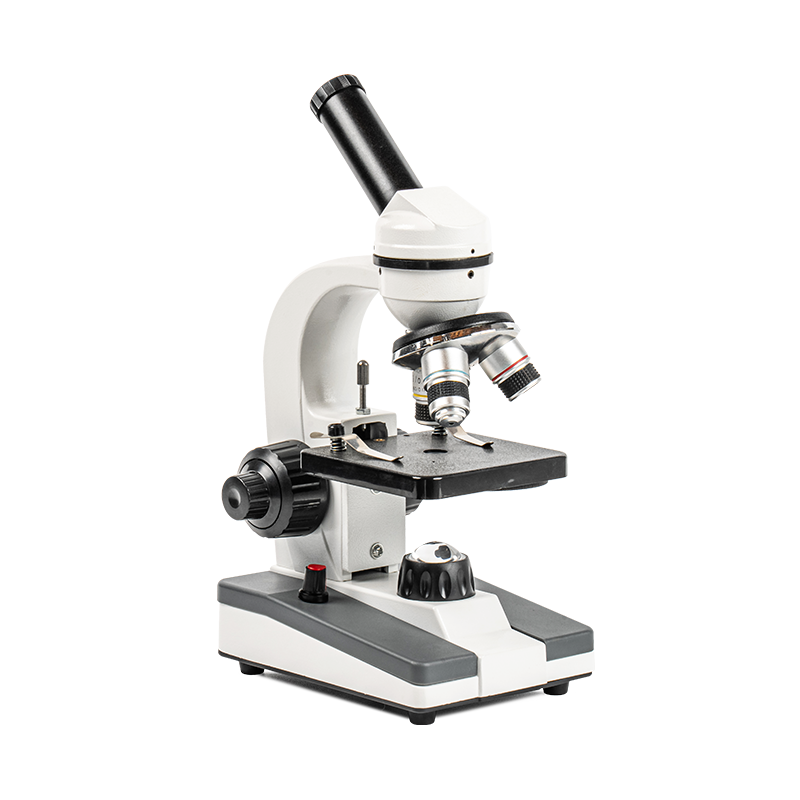

Ensuring the stability of a student microscope during use is crucial for accurate observations and ease of operation. Here are some aspects to consider regarding stability and anti-slip features:

Base Design: The foundation of stability in a microscope lies in its base design. A well-designed base is characterized by its width, providing a broad platform for support, and its weight distribution, ensuring a low center of gravity. A wider base offers increased stability by minimizing the risk of tipping or wobbling during use, especially when manipulating the microscope or adjusting viewing parameters. Materials such as heavy-duty metals or high-density plastics are preferred for their durability and ability to withstand repeated use without deformation or compromise to stability.

Rubber Feet: Anti-slip rubber feet or pads play a pivotal role in anchoring the microscope securely to the surface upon which it sits. These rubberized elements serve to create friction between the base of the microscope and the underlying surface, effectively preventing unintended movement or displacement, even on smooth or slippery laboratory benches or desks. The strategic placement of these rubber feet, often at the corners or along the perimeter of the base, maximizes contact and enhances stability, ensuring uninterrupted focus and observation without the need for constant readjustment.

Adjustment Mechanisms: The stability of a microscope is intricately linked to the performance of its adjustment mechanisms, including focusing knobs and stage controls. Precision-engineered components with tight tolerances facilitate smooth yet controlled movements, allowing users to manipulate the microscope with confidence and accuracy. Minimal backlash or play in these mechanisms ensures that adjustments remain stable once set, preventing drift or unintended shifts in focus or specimen positioning. Ergonomically designed controls further enhance stability by promoting comfortable and intuitive operation, minimizing hand fatigue and maintaining consistent performance over extended periods of use.

Locking Mechanisms: Microscopes equipped with locking mechanisms offer an additional layer of stability and security, particularly when precise adjustments need to be maintained over time. Locking mechanisms may be integrated into various components of the microscope, such as the stage, focusing mechanism, or interpupillary distance adjustment. By securely locking these elements in place once the desired parameters are achieved, users can confidently conduct observations without the risk of inadvertent movement or disruption. Locking mechanisms come in various forms, including clamps, knobs, or levers, each designed to provide reliable stability while remaining easily accessible for adjustment when necessary.

Quality Construction: The stability of a microscope is inherently tied to the quality of its construction and materials. Premium-grade materials, such as aircraft-grade aluminum, stainless steel, or reinforced polymers, are chosen for their exceptional strength, rigidity, and resistance to deformation or corrosion. Precision machining and manufacturing processes ensure tight tolerances and exacting specifications, resulting in components that fit together seamlessly and operate smoothly with minimal friction.

English

English Español

Español عربى

عربى 中文简体

中文简体