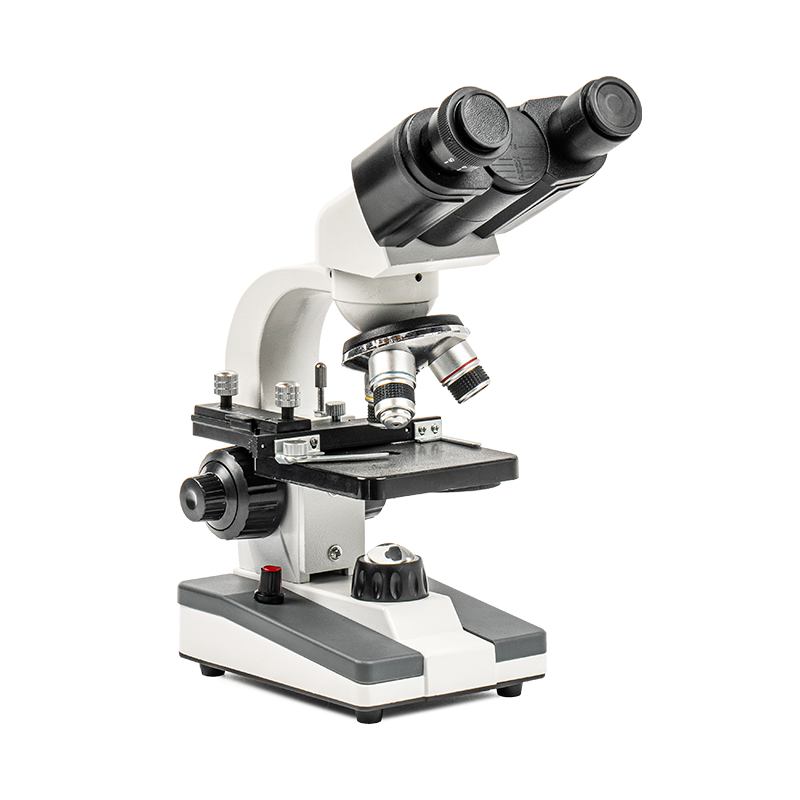

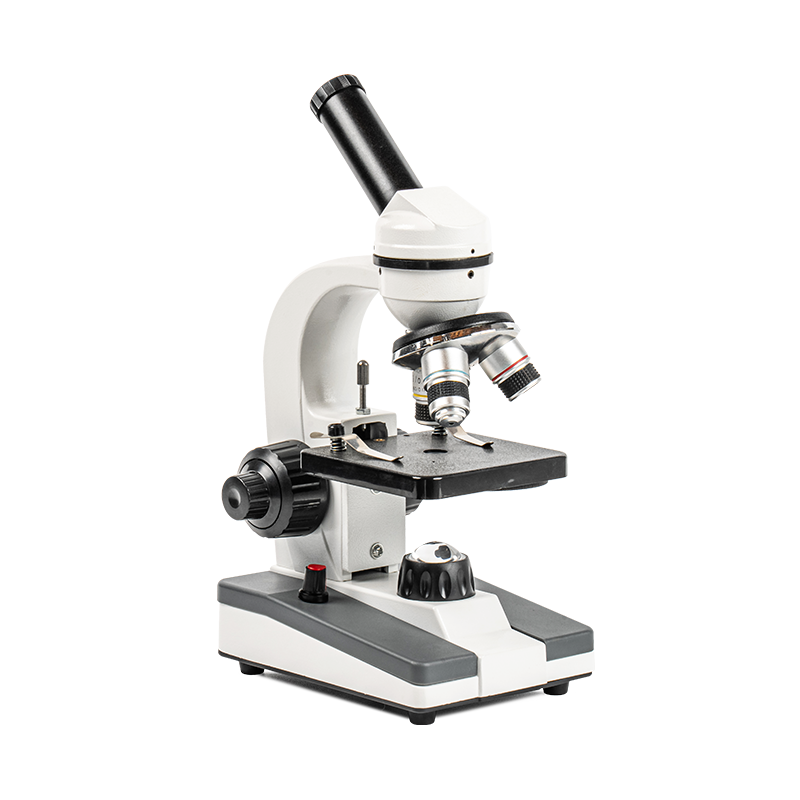

Metallurgical microscopes are indispensable tools in the field of metallurgy, providing crucial insights into the microscopic structure and crystallographic characteristics of metals. These instruments excel in their ability to magnify and resolve fine details, enabling clear observation of features such as grain shapes, sizes, and arrangements within metal samples.

At the heart of their capability lies the high magnification and resolution of metallurgical microscopes. They boast a range of magnification levels that allow researchers and technicians to zoom in on minute structures that are not visible to the naked eye. This capability is essential for studying the internal architecture of metals, which often contain complex microstructures that influence their mechanical properties and performance in various applications.

Metallurgical microscopes also offer a variety of observation modes tailored to different analytical needs. Polarized light microscopy, for instance, is particularly valuable for analyzing the optical properties of crystalline materials. By examining how light interacts with the metal's structure under polarized light, scientists can deduce information about crystal orientations, stress states, and optical anomalies like birefringence.

In practical application, preparing metal samples for examination is a meticulous process. Techniques such as grinding, etching, and polishing are employed to create smooth, flat surfaces that reveal the true microstructure of the metal. This preparation is crucial as it ensures that observations made under the microscope are accurate and representative of the material's inherent characteristics.

Furthermore, the integration of digital imaging technologies enhances the functionality of modern metallurgical microscopes. Digital cameras attached to these microscopes enable real-time capture and storage of high-resolution images. This not only facilitates detailed examination but also allows for precise measurements and quantitative analysis of grain sizes, grain boundaries, and other microstructural features. Advanced image processing software further aids in image enhancement, making it easier to distinguish fine details and anomalies within the metal samples.

English

English Español

Español عربى

عربى 中文简体

中文简体